GLI Hanger

GLI-Hangar works by receiving GPS satellite signals through an antenna located on the roof of the hangar and moving the signal inside the hangar. It enables the GPS signal to be available inside the hangar (and only the hangar), allowing for ongoing testing and troubleshooting of GPS/avionics systems indoors. Delays of maintenance due to inclement weather or the placement of other aircraft is mitigated. The ability to work on the GPS navigation equipment is not dependent on the aircraft being outside or the hangar door being open.

Send Enquiry for GLI Hanger

In Aviation, there is increasing emphasis on operational efficiency and cost control. Operational efficiency mandates that airlines have cost-effective airplane hangars that support productive maintenance activities. It is all about saving time. If you can save an hour here or there by NOT having to move aircraft out of the hangar, it adds up. Save Money, Save Time, Minimize Labour

■ Save On Utilities – heating and cooling costs are minimized as hangar door can remain shut. When large hangar doors are opened, heat is quickly displaced with cold outside air. When the doors are closed, the heating cycle must start all over again. One case study noted the cost to heat a 400’ x 800’ hangar at $150,000 per year. Utility costs are usually the largest single expense for facilities. Facility Managers can have significant impacts on their operating costs by understanding what opportunities exist to reduce or control utility costs.

■ Use Less Manpower – personnel not required to move aircraft in and out of hangar for GPS avionics testing This means you will not need a tow supervisor, brake person, tow vehicle operator, a nose walker, wing walkers or a tail walker just to test the GPS avionics system. “Conservatively, use $500/week for maintenance hangar… cost of 1-2 aircraft per week is typically $250/each aircraft to tow outside… just labor, we do not power up the aircraft” … Small Aircraft Manufacturer

■ Use Less Fuel – no need to start up aircraft, it remains in hangar during GPS avionics testing. No one can deny the cost of jet fuel is enormous! – “It easily exceeds $1000/wk just in fuel costs for moving 3-4 aircraft out from under the sunshades” … Lieutenant Colonel, Air National Guard. “There is an internal cost for the personnel and the tow. I would assume roughly around $150-$200 for each aircraft.” …International Supplier of Military Aviation Electronics

■ Use Less Time – GPS avionics equipment can be maintained at any time, no need to wait for an outside opportunity “Sometimes the airplanes are jacked up, so it is not possible at all to bring them outside” … Aircraft Maintenance Consultant

How Does It Work?

GLI-Hangar works by receiving GPS satellite signals through an antenna located on the roof of the hangar and moving the signal inside the hangar. It enables the GPS signal to be available inside the hangar (and only the hangar), allowing for ongoing testing and troubleshooting of GPS/avionics systems indoors. Delays of maintenance due to inclement weather or the placement of other aircraft is mitigated. The ability to work on the GPS navigation equipment is not dependent on the aircraft being outside or the hangar door being open.

Let Us Help!

Bringing the GPS signal inside an aircraft hangar can be challenging, GPS Source can help. Based on the dimensions and physical layout of your hangar, we can help you design an optimal system at no charge. GPS Source will help you determine the optimal place to install the GPS Smart Controller (GLI-METRO), determine the correct gain to set the controller, the correct length of cable to buy and the best location for the outdoor antenna. GPS Source has helped customers design systems for a variety of hangars all over the world. We have solutions for hangars that are 10,000 to 200,000 square feet. There is no charge for calling us to discuss your unique challenges.

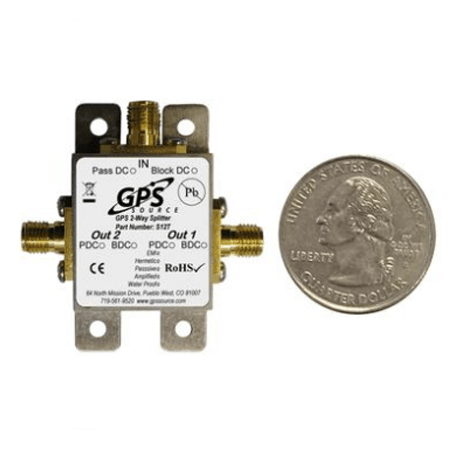

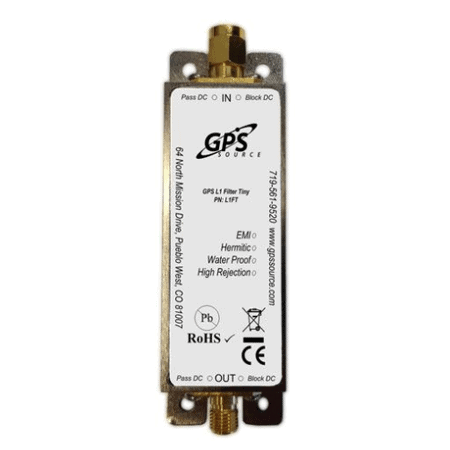

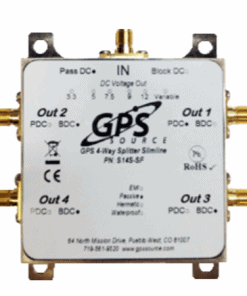

Related products

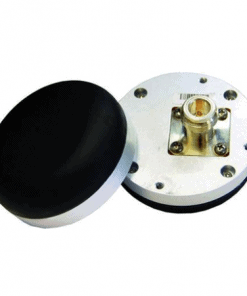

Send Enquiry for Ruggedized L1L2 Antenna, Passive (Transmit) Bottom Mount

GPS Solutions

Send Enquiry for S14S – GPS Slimline Splitter

GPS Solutions

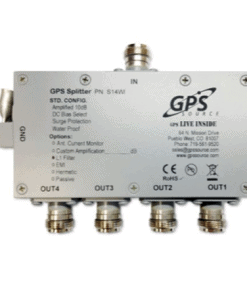

Send Enquiry for S14WI – GPS Wireless Splitter –

GPS Solutions

Send Enquiry for S18 – GPS Standard Splitter

GPS Solutions

Send Enquiry for S18WI – Wireless Splitter

GPS Solutions